Ferrari 250 – the name sounds familiar. Of course, it does: 250 GTO, 250 SWB, 250 Testarossa, 250 California, 250 Tour de France... but what exactly does the ‘250’ prefix mean? Well, it’s actually quite simple; it stands for 250cc, roughly the cubic capacity of a single cylinder. It was the same with all Ferraris until the mid ’80s – 166, 275, 340, or even the Daytona’s 356, which has a single-cylinder capacity of 356cc. So to known the size of the engine in the car all you have to do is multiply the number by the number of cylinders, 12 in most cases here. So, the 250 engine in effect displaces 250x12, or 3,000cc, or three litres.

Now, Ferrari has had several V12 engines over the life of the company. This one, however, is the first, and is widely considered to be the greatest. Legend has it that work on it started even before company founder Enzo formally launched the road-car firm in 1947. The engineer tasked with the job, Gioacchino Colombo, was well-known to Ferrari from his days at Alfa Romeo, and Ferrari contracted with him to start working on a V12. Now, making a new engine of this complexity and complication was considered foolhardy at the time. The Second World War had just ended, the economy of Europe was in shambles, and where other car companies were happy upgrading their earlier machinery, Enzo decided to go ahead with his 12. Even more insane was the fact that the engine (initially, at least) would displace only 1,500cc – the capacity needed at the time for racing in supercharged form. Ferrari road cars would use it unblown.

Enzo Ferrari, however, was practical too. While the specification of the engine was ambitious, he decided, early on, to avoid the use of cutting-edge and generally untested metals and new tech, most of it filtering down from the aviation industry. During the war, Enzo made parts for aircraft engines, so he knew what he was doing. The only exception he made (and only because he couldn’t avoid it) was the use of high-tech bearings, from Vandervell in England.

Legend has it that Colombo was so enthused by the project, he started working on it when he was on holiday. The design of the engine actually had a lot in common with racing motorcycle engines. But while a lot of the philosophy was borrowed from bikes, Colombo took it to the next level. Designed and engineered to make maximum power at an astronomical for- the-time engine speed of 7,000rpm – remember cars in this era normally made peak power at around 3,500rpm or 4,000rpm – the engine was unusual in many ways. For one, it was an over-square engine, which means the bore of the cylinder is much larger than the stroke of the piston. A relatively short stroke allows the engine to achieve high engine speeds, as the piston doesn’t have to travel a long way up and down (typically, long-stroke diesels have the opposite problem) and, with 12 cylinders, the engine also has lower individual reciprocating loads. In expanded 250 form, the bore and stroke on the 2,953cc engine worked out to a crazy 73x58.8 (a wide-bore centre spacing of 90mm allowed for this). No wonder the 168B, as the 250 engine was called, could spin like a top.

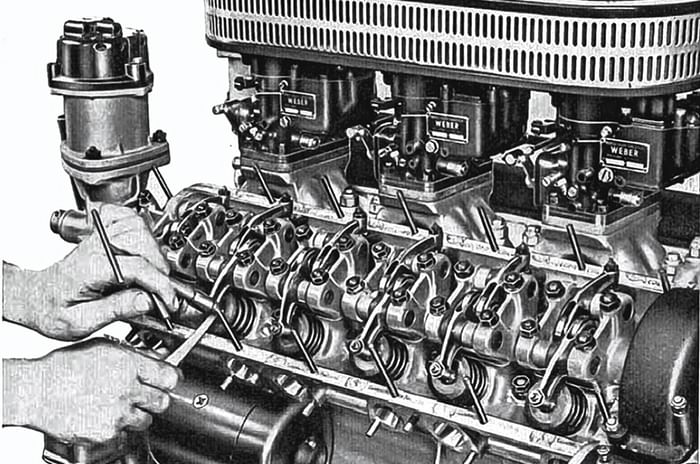

The valve gear, however, was kept light, with a only a single-cam setup and long rockers for intake and exhaust valves. Drive for the cam was taken via a roller chain. Award-winning author Karl Ludvigsen in his 400-page ‘encyclopedia’ on the automotive V12 engine mentions that while this was common practice on aero engines, it was unusual for a high-speed automotive engine.

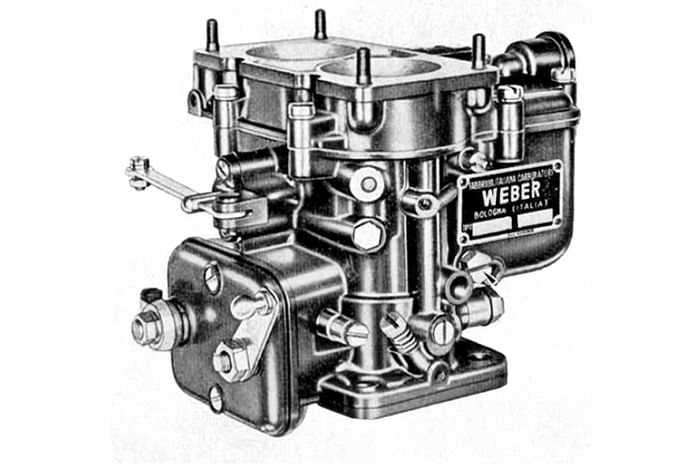

What also played a key role in making more power was carburation. Over the years, a number of Weber’s single-float twin-barrel carbs were used – often six of them with one butterfly and venturi per cylinder: as effective as early fuel injection. The Webers also give the 250 engine its characteristic look – the 12 tall velocity stacks or trumpets that sit above the carbs clearly visible over the black or red crackle cam covers.

Where 250 engines put out between 240hp and 280hp, the competition’s engines produced even more. As the years went by, the 250 engine evolved into the 275, 365, and, finally, the 400i. A lot changed by the time the engine came to power the 365 GTB4 or the Daytona, but it was fundamentally still Colombo’s engine. In 1968, the Daytona achieved a speed of 280kph, making it the fastest production car in the world – not bad for an engine that started life in 1946 or 1947.