The old adage ‘Racing improves the breed’ has been milked by car companies too often to justify their high spends in motorsport. No doubt, a lot of innovations born on the race track have found a way into production cars. But how much of this tech can be felt by car owners? Audi is out to prove that race car tech can directly lead to better road cars and to this effect, has tom-tomed the fact that LED lighting was actually pioneered on its Le Mans racers. The Audi R15 LMP1 first used LEDs for daytime-running lights on the track back in 2009 and its successor, the Audi R18, went the whole hog to use full-LED lights.

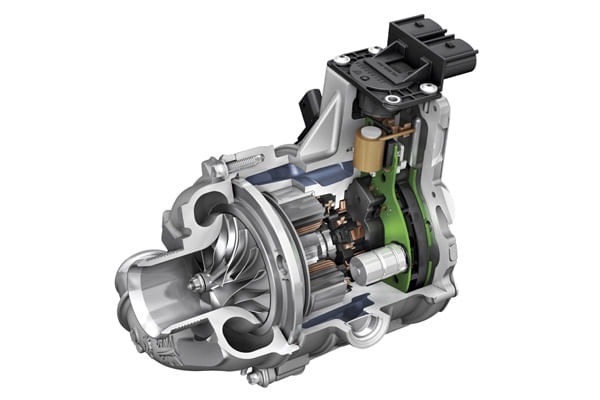

The latest innovation to find its way under an Audi bonnet is the electric turbocharger, and the mega-quick SQ7 SUV is the first series-production vehicle to be equipped with one. The electric turbo, which essentially aids two conventional exhaust-driven turbo chargers, is seen as the ultimate solution to beat a turbocharger’s infamous ‘turbo lag’ which has been the bane of bigger diesel engines.

The technology can be traced back to Audi’s efforts in Le Mans and World Endurance Championship – electric turbo first debuted on the radical 2014 Audi e-tron Quattro and amazingly, the boffins at Ingolstadt have managed to transfer the technology from race to road in just over two years.

Engineered to adhere to the new FIA WEC regulations for the 2014 season, the e-tron Quattro was a resounding success as it won the Le Mans and finished a close second in the championship standings.

In the 2014 e-tron Quattro, the single turbocharger of the internal combustion engine was linked to an electrical recovery unit, which made it possible to convert thermal energy of the exhaust gas into electric energy.

This was in turn stored in the flywheel energy storage system and when the car accelerated, could be either deployed to the front axle or sent back to the turbocharger.

Similar to the approach applied in Formula 1, this was done to pre-spool the turbocharger – which meant less turbo lag, which in turn meant quicker acceleration, especially out of slow and medium-speed corners, since the regulations did not permit the front axle being driven at speeds below 120kph. Spinning the turbo with electric energy countered this issue, maximising corner speeds and priming the turbo for the straights.

Of course, with the SQ7 being a road car, such a complex system is not called for as it is not regulated by FIA rules. With two variable-sized turbochargers already optimising the boost range, a third, pure-electric turbo, has been added to improve off-idle throttle response – mimicking a large, naturally aspirated engine at low engine speeds.

This allows the new 435hp 4.0-litre diesel also slated for the fourth-gen A8 and a new, top-of-the-line Q8 SUV, to produce locomotive levels of torque just off idle – a mental 900Nm at just 1,000rpm!

The two conventional turbos, run sequentially, with the smaller one engaged at low throttle loads and the larger unit activated at higher loadings.

But even two turbochargers cannot get around the marked loss in boost when the driver backs off the throttle, as exhaust pressure is dramatically reduced.