New energy recovery tech could result in a leap forward in fuel consumption, while also reducing production costs, with KERS-based systems set to be introduced around 2020

Volvo is testing its new energy recovery system on a test S60 saloon that will help reduce fuel consumption by more than 25 percent, while costing only a quarter of the factory price of a conventional battery-electric hybrid.

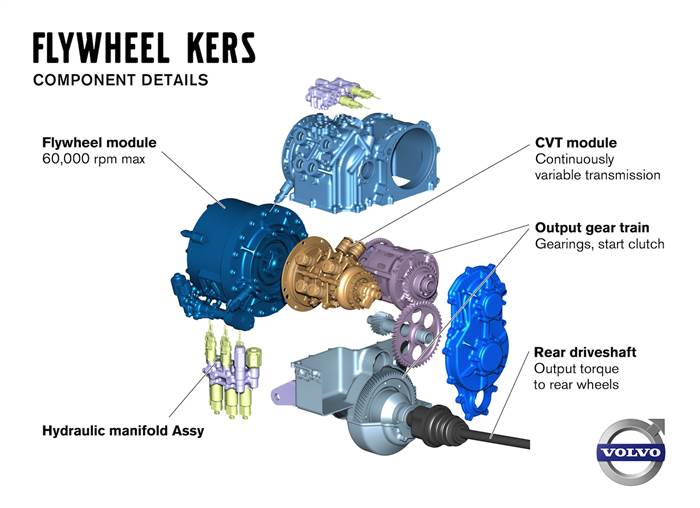

The British-designed flywheel energy recovery system, Flybrid KERS (Kinetic Recovery System) has been fitted to the rear axle of the test S60 sedan, and can be used to assist the petrol engine that drives the front wheels. It can be used to enhance performance, knocking 1.5 seconds off the 0-100kph time of the 254bhp S60 T5. The flywheel system is based on a conventional flywheel which runs at a maximum of 60000rpm and can deliver up to 80bhp. Kinetic energy is stored in the flywheel – which runs in a true vacuum – for 20 minutes before it begins to disperse. At full deployment, the S60 prototype gets a 10-second power boost.

However, Volvo says that conventional brakes develop such a huge amount of energy that even gentle braking for eight seconds will fully recharge the flywheel. A Toyota Prius hybrid would take three times as long to store the same amount of energy, the company claimed. This new system is more sophisticated than the previous flywheel systems because it drives the rear wheels through a continuously variable transmission built by Torotrack. Using a geared connection between the rear wheels and the flywheel also means that the flywheel can be spun up to speed more quickly than by direct drive from the rear wheels.

The core of the flywheel is made from steel and it is wrapped in a 10mm layer of carbonfibre. The flywheel runs in a vacuum and drives the Tototrack CVT – which uses tilting rotary discs to transmit the power. This, in turn, drives a series of gears slowing the drive output so it can then directly drive the car’s rear axle. The whole set-up in the prototype weighs around 60kg, far less than a battery-electric hybrid.

While this particular rear-drive set-up is unlikely to reach production, a future version will see the flywheel and Torotrack ‘box integrated into a front-wheel drive transmission. Volvo engineers told our sister magazine, Autocar UK that “some form of KERS system” would be inevitable on production cars after 2020.

While most energy recovery systems work best in urban traffic – when the driver is using the brakes often – they are much less effective on motorways. However, Flybrid engineers said that, at motorway speeds, the flywheel could be re-charged while the engine is driving the wheels.

Because it takes less than 30bhp to propel a car at a 113kph level cruise, the energy stored in the flywheel could be enough to continue driving the car at 113kph for almost a kilometer, opening the possibility of high-speed ‘engine blipping’, where the engine drives the car for about a kilometer, before the flywheel takes over for the next kilometer.

Comments

Member Login

Personal Details

No comments yet. Be the first to comment.