It is well known that paper is not the only printer-friendly material and that, thanks to modern computer technology, there is no need to stay in the rather limiting world offered by the first two dimensions.

While 3D printing promises to change the way we conceptualise, design, manufacture, and consume day-to-day things in the foreseeable future, what about cars?

If you did happen to see the recent Bond movie, Skyfall, you may have cringed at the sight of an Aston Martin DB5 apparently being riddled with bullets. But you'd have relaxed rather more had you known that it was, in fact, it was merely a 3D printed model.

But what about a real car – something you can get in and drive? You couldn’t print one of those, surely?

At the recent Detroit motor show, printed car pioneer Local Motors did just that - they printed a car at its stand, with the aim of driving it away at the end of the show. And just to prove that they weren’t kidding, they showed one they’d made earlier too.

The theory behind the 3D printed car is so compelling that it forces you, at least at first, to put to one side some of the thornier issues that may thwart it becoming a commercial reality.

“It’s all about the tooling,” the positively evangelical Elle Shelley, Local Motors’ chief marketing officer told our sister publication Autocar UK. “Guess how many parts this car has,” she insists, pointing at the car they call the Strati.

“Forty-seven,” she says. “A conventional car has 35,000.”

If the Local Motors dream comes true, it will work like this: the world will become populated by so-called micro-factories, all printing cars that are not only crowd-funded but also crowd-designed. People enter competitions locally, a winning design is selected and that’s what gets printed. “You don’t need to make a million cars before returning a profit to your investors,” says Shelley. “You’ll turn a profit on 1,000 cars.”

Moreover, while it might take five years or more for a conventional car manufacturer to design a new car, the Strati went from an idea to being driveable in just five months, albeit with a little help from the powertrain and running gear of a Renault Twizy.

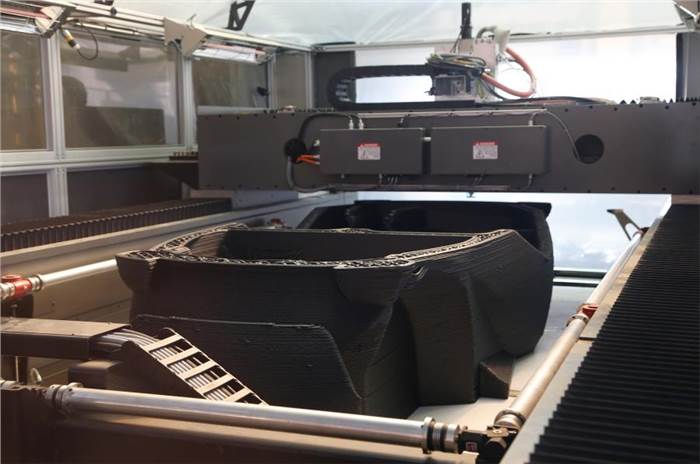

It takes 44 hours to print, using carbonfibre-reinforced plastic, a couple of hours to mill the resulting rough surfaces into something smoother, and then perhaps a day to clip all the panels together “like Lego”, as Shelley describes it.

Unlike owners of normal cars who can only either sell or keep the car they have bought, if you then get bored with your car’s design, you just take it back to the factory, where it will be melted down and turned into something else. They call it ‘upgradeable hardware’.

The Strati is not actually a production car, although Local Motors says that something similar but with proper weather equipment, will be in production before the end of year, for “between $18,000 (approximately Rs 11.37 lakh) and $30,000 (approximately Rs 18.95 lakh)”. It weighs less than 750kg, which doesn’t sound like much, but is actually half as much as the Twizy, that lends its battery, electric motor and suspension. Then again, you can power it by pretty much anything that fits – up to and including, says Shelley, “the Porsche engine we’re working on”.

There are many issues with such an innovative approach to car manufacturing. Shelley confirms that there is a lengthy homologation process that needs to be followed. Also, while Local Motors plans to open more than 100 micro-factories around the world, right now there are just three - located in Las Vegas, Washington DC and Phoenix.

Even so, Local Motors is aware that even if the Strati and its future printed cars find the legislative going tough in the US, there are lots of other places around the world where the demand could be immense. “Think of sub-Saharan Africa,” says Shelley. “That’s a huge opportunity.” Looking at the potential demand for such a simple vehicle, for which spare parts can be printed locally as per the demand, you can then see the point.

It would be easy to titter at Local Motors and what it describes as “the car that will change the world”. They are clearly passionate about their creation and spectacularly brave in their attempts to bring it to market in a way that owes precisely nothing to the principles of car manufacturing laid out by Henry Ford over a century ago that live with us to this day.

What I will say is that although I have no better idea than you whether Local Motors will succeed or not, you don’t need a PhD in engineering to see the sense of printing at least components for cars. Quick, less wasteful than conventional processes, and able to be changed at the click of a mouse, it is, if not the future of car manufacturing, then certainly part of it.

And a whole car? Time was when people considered the car itself a passing fad. We may yet one day titter on the other side of our faces.

Andrew Frankel

Comments

Member Login

Personal Details

No comments yet. Be the first to comment.